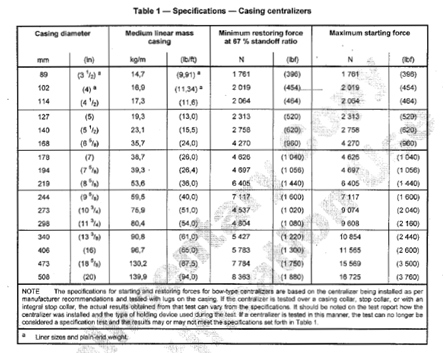

Centralizer

The main scope of this testing is to evaluate the performance of bow spring Centralizers, solid centralizers& stop collar with respect to criteria indicated in API 10D, API 10TR5, API 10D2.

TEST CATEGORIES OF BOW SPRING CENTRALIZERS:

I. Starting force (As per API)

II. Running force (As per API)

III. Restoring (As per API)

TEST CATEGORIES OF SOLID CENTRALIZERS:

I. Measurement of Friction Factor Using the Pin-on-Disk Method

II. Measurement of Wear Using the Pin-on-Disk Method

III. Impact Test Consisting of Dynamic Loading Applicable to Hinged-type Rigid Centralizers

IV. Static Axial Loading Simulating Running the Centralizer through Restrictions.

V. Test to Simulate Side Loading of the Centralizer

VI. Test to Simulate Static Loading of Centralizer and Stop Collar

VII. Pull-apart Test for Centralizers with End Rings

Cementing Plug

There are two types of cementing plug are used for primary cementing. The main scope of this testing is to evaluate the performance of Cementing Plug. The used plugs are Bottom Plug and Top Plug.

1. Bottom plug used to wipe drilling mud and provide passage to trailing cement slurry. After designed pressure rupture area burst. Bottom plug test for rupture area burst pressure that is 300-400psi.

2. Top Plug has to withstand 5000 psi so it need to test for 5000 psi back pressure for at least 15 min.

NOTE: Top Plug bump pressure and Bottom Plug rupture pressure may vary as per requirement

Cementing Float Equipment

The main scope of this testing is to evaluate the performance of cementing float equipment with respect to criteria indicated in API RP10F.

FLOAT EQUIPMENT PERFORMANCE CRITERIA:

I. Durability under down hole conditions

II. Differential pressure capability under from below

III. Ability to withstand force exerted through cementing plugs from above

IV. Drill ability of the equipment

V. Ability to pass lost circulation materials

VI. Reverse flow resistance of casing fill up valve

TEST CATEGORIES:

There are two type of tests are mandatory to qualify the float.

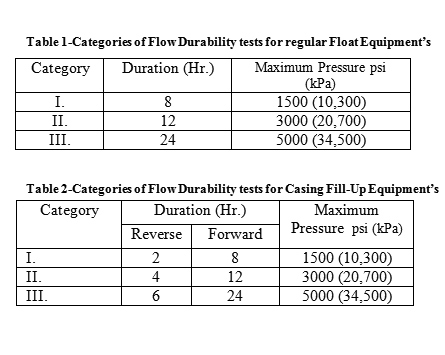

1. Durability test.

2. High pressure/High temperature test.

1. DURABILITY TEST

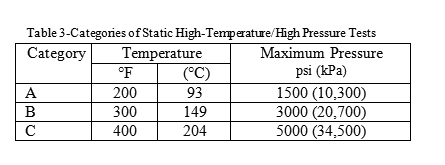

2. HIGH PRESSURE/HIGH TEMPERATURE: